Specific Cracks and Water Leakages

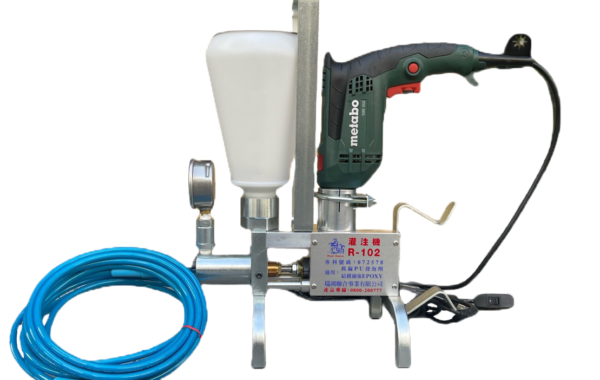

Water leakage can cause severe damage to buildings and structures, making it essential to use practical solutions to stop water leakage. Currently, the most popular method is using a high-pressure grouting machine, which can be used in a variety of situations including stopping leakage and structural reinforcement and repair. By injecting PU injection agents using a high-pressure grouting machine wit injeciton packers, water leakage can be stopped and prevented from causing further damage. It’s crucial to address water leakage promptly to avoid costly repairs in the long run.

1. Soil Improvement Injection

- Depending on the thickness of the wall, use a long drill bit to drill through the RC wall until reaching the soft soil layer. Install a long injection packer depending on the area, with an interval of 30 cm. Using a high-pressure grouting machine, inject a foaming agent into the injection packers.

- If the space between the concrete wall and the soft soil layer is large, inject a hydrophobic or hydrophilic foaming agent first. Follow it up with an elastic or rigid foaming agent. If moisture or leaks still occur on the surface of the concrete after injection, an additional foaming agent may be necessary to completely fill the gap.

2. Structural Cracks Leakage

- Identify the location and extent of the crack in the concrete structure.

- Using a drill, create holes around the crack at an angle. Ensure that each hole is spaced 20-30 cm apart and drilled to a depth of at least 2/3 of the thickness of the structure. If the crack has an irregular shape, it may be more effective to drill between the left and right sides of the crack for maximum coverage. Insert injection packers into the holes that have been drilled around the crack.

- If the crack is leaking water, use a high-pressure grouting machine to inject a single-component hydrophobic or hydrophilic foaming agent into the holes. If the crack is dry, a rigid or elastic foaming agent may be used.

- Wait for the foaming agent to harden and cure, and then remove the injection packers.

3. Construction Joints & Expansion Joints Leakage

- Identify the location and extent of the joint in the concrete structure.

- Using a drill, create holes around the joint at an angle, with a distance of 20 – 30 cm between each hole. The holes should be drilled to a depth of at least 2/3 of the thickness of the structure and insert injection packers into the holes.

- Using a high-pressure grouting machine, inject a single-component hydrophobic or hydrophilic foaming agent into the holes until the foaming agent seeps out of the drill holes. Wait for the foaming agent to harden and cure, and then remove the injection packers.

- If leaks still occur after the initial injection of the foaming agent, additional injections will be needed to ensure a complete seal.

4. Water Gushing Leakage

- Using a drill, create a hole at an angle in the concrete structure, aiming towards the water outlet point, and insert injection packers into the drilled hole.

- Remove any loose wall material surrounding the point where the water is gushing, and if necessary, install a PVC pipe at the gushing water point with a valve at the end to control the flow of water. Mix a water-stopping powder with water and use it to seal the edge of the PVC pipe.

- Using a high-pressure grouting machine, inject a super rapid foaming agent (OH-9T) into the PVC pipe. Check if the foaming agent is flowing out of the valve, and if it is, shut the valve immediately and begin injecting large amounts of the foaming agent.

- Once there is no longer any water leakage, remove the PVC pipe and inject a hydrophilic, elastic, or rigid foaming agent as needed to ensure a complete seal.

5. Tunnel Rings Leakage

Ring Segment Cracks

- Drill holes directly on top of the crack to a depth of approximately 25 cm.

- Insert injection packers into the holes and use a high-pressure grouting machine to inject a hydrophilic, elastic, or rigid foaming agent.

Segment Joint Cracks

- Drill holes through the water-stop strip directly between the ring segments.

- Insert injection packers into the holes and use a high-pressure grouting machine to inject a hydrophilic, elastic, or rigid foaming agent.

Grouting Hole Leaks

- Remove the cap from the grouting hole and drill a hole through it using a 5.1mm drill bit.

- Insert a grease nipple into the hole and use a high-pressure grouting machine to inject a hydrophilic, elastic, or rigid foaming agent.

6. Window Frame Leakage

- Identify the location of the leak in the aluminum window frame joint with the concrete structure (RC).

- Using a drill, create a hole at an angle at the bottom of the joint between the aluminum window frame and the concrete structure (RC), spacing the holes approximately 20-30 cm apart.

- Install injection packers into the holes, and then use a high-pressure grouting machine to inject hydrophilic, elastic, or rigid foaming agents into the drilled holes until the foaming agent seeps out.

- Wait for the foaming agent to harden and cure, and then remove the injection packers.

7. Honeycomb Leakage

- Identify the location and extent of the honeycombing in the concrete structure.

- Drill holes around the structure at an angle, with a distance of 20 – 30 cm, and insert injection packers to a depth of at least 2/3 of the thickness of the structure.

- Use a high-pressure grouting machine to inject a hydrophilic foaming agent into the drilled holes until the foaming agent seeps out.

- Wait for the foaming agent to harden and cure, remove the injection packers, and clean any excess material off the surface of the structure.

Have questions or inquiries? You’re welcome to contact us anytime.